Supporting the construction of the century: supplying aggregates for the Eastern Exit Tunnel in Ufa

Supplier company:

LLC "YUNK"

Customer:

LLC "Limakmarashchavtodorogi"

Delivery times:

2023–2024

Delivery volume:

101,000 tons of non-metallic materials

Object:

Construction of the Eastern Exit Tunnel in Ufa

Construction

Supply of aggregates for the Eastern Exit Tunnel

Participation in a key infrastructure project in Bashkortostan. The Eastern Exit Tunnel is one of the most significant and anticipated transport hubs in Ufa. Our company is proud to have contributed to this large-scale project by assuming responsibility for providing high-quality aggregates for construction. The timing and quality of construction of the entire tunnel depended on the reliability of the aggregate supplier.Problems

The challenge we accepted: our primary objective was not simply to supply aggregate, but to become a reliable link in the complex construction chain of a strategic facility. We had to solve two key problems:

Challenge #1:Uncompromising quality. The cast asphalt concrete used in the tunnel required M1400 aggregate with only Group 1 flakiness. Any deviation from GOST standards could jeopardize the strength and durability of the pavement, which is subject to enormous loads.Challenge #2:Continuity at risk of missed deadlines. The 100,000-ton volume and tight construction deadlines meant that the slightest delay in deliveries would paralyze the work of hundreds of pieces of equipment and personnel, delaying the completion of the project.

Solution

YUNK's Integrated Approach: From Quarry to Site. We offered the customer not just a supply chain, but a streamlined system where every process was under control.

Expert Raw Material Selection. We utilized our quarry, which produces high-strength crushed stone (M1400), and configured our production lines to ensure a flakiness of less than 10% and a complete absence of clay particles.Iron-clad logistics. We organized a 24/7 vehicle fleet and dispatch service. All deliveries were synchronized with the customer's schedule literally hour by hour.

Proactive Planning. To prevent truck downtime, we created buffer zones for unloading in the immediate vicinity of the site. This allowed the equipment to operate smoothly, without waiting in queues.

Multi-stage laboratory testing. Each batch of crushed stone and screenings underwent double testing:

- Incoming inspection at the quarry.

- Outgoing inspection before shipment to the site. We monitored strength, frost resistance, flakiness, and dust and clay particle content. Test reports were included with each batch.

Result

Results We're Proud of. Thanks to our team's coordinated work and the solutions we proposed, the client achieved impressive results:

- The project was completed ahead of schedule. The Eastern Exit Tunnel opened on March 21, 2024, three months ahead of schedule. Our reliability was one of the factors that allowed us to expedite construction.

- A tangible infrastructure effect. The project has dramatically changed the transportation situation in Ufa: congestion in the city center has been reduced by 30%, and the time to access the M-5 Ural federal highway has been reduced from 50 to 10 minutes.

- Strengthening reputation. Participation in such a landmark project, recognized by regional and Russian government officials, confirmed SUNK's status as a reliable partner for major infrastructure projects.

Customer review

„

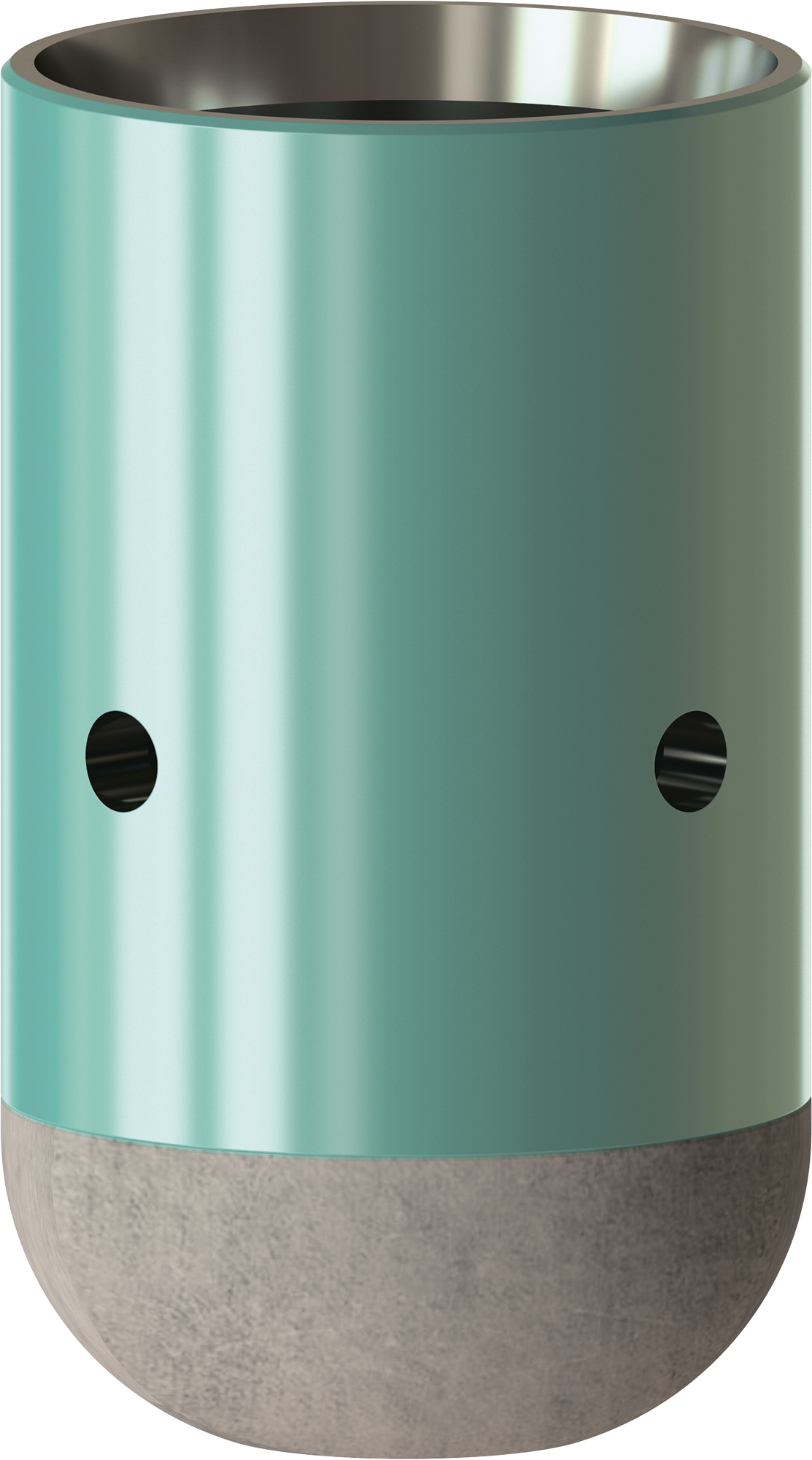

используемая продукция

Другие

Проекты

Our engineers will prepare a commercial proposal within 24 hours

We use cookies to improve website performance.